Interior Single-Wall Metal Chimneys

Our inspectors look for exposed interior single-wall metal chimneys that are not continuously enclosed where they extend through closets, storage areas, or habitable spaces, or where the surface of a chimney could come into contact with people or combustible materials.

We inspect for interior single-wall metal chimneys for distances less than 18 inches from wood frame walls or combustible materials.

Inspecting for interior single-wall metal chimneys 18 inches or under in diameter that are less than 2 inches from non-combustible walls are also on our list of items along with interior single-wall metal chimneys over 18 inches in diameter that are less than 4 inches from non-combustible walls.

There are certain types of vents allowable to be adjacent to combustible materials.

Type B Vents

Type B vents are vents suitable only for listed, draft-hood equipped, gas-fired appliances, including most domestic heating and hot water systems.

They may not be used with any of the following appliances:

- wood-burning appliances, such as fireplaces and wood-burning stoves;

- incinerators;

- oil-fired equipment;

- coal-fired equipment;

- any appliance that burns anything other than liquid petroleum or natural gas; or

- any appliance that produces flue gasses that exceed 480° F (249° C).

Type B vents must be equipped with their own special chimney caps. If the cap is damaged or lost, it should not be substituted with something not recommended by the manufacturer. The clearance required from combustible materials is printed on the flue’s exterior metal surface, and is generally 1 or 2 inches.

Type L Vents

Type L vents are designed for venting approved oil-fired and natural-gas appliances that produce draft hood flue gasses that do not exceed a temperature of 570º F, or 926º F for 10 minutes in an over-fire situation. The minimum clearance from combustible materials is generally 3 inches. Type L vents should not be used to vent coal- or wood-fired appliances.

It may be difficult to tell the difference between Type L and Type B vents because they are made from similar components, but the vent type should be clearly printed on the vent. Both are double-walled, although Type L vents generally have a stainless steel inner wall, while Type B vents do not.

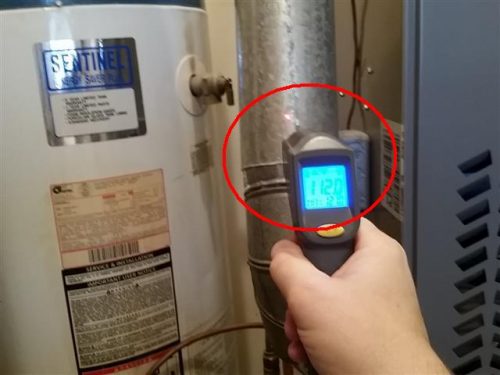

Regardless of the vent type, we check for the following defects:

- deterioration of the outer wall, which is likely caused by failure of the inner metal lining;

- violation of roof clearance requirements. All metal vents must terminate at least 2 feet above the roof surface and anything within 10 feet of the vent, such as the crest of a roof ridge;

- missing components, such as a chimney cap;

- firestops not installed at either the top or bottom side of the joist where the vent passes through floors or the roof. The firestop should allow a fire-resistance rating equal to or greater than the floor or roof assemblies through which the vent passes;

- blocked bird screens, often caused by freezing moisture in cooler climates;

- crucial joists, rafters or other load-bearing structural members that have been cut to allow for the vent to pass. Plumbing and electrical lines should also not be disturbed by the vent; and

- whether the vent is too high or too low. Manufacturers may set minimum and maximum height requirements for the whole vent assembly, such as the AirJet Type L vent, whose minimum height is 6 feet and maximum height is 30 feet.

Our inspectors may recommend that extra corrosion resistance for vents be provided by a stainless steel cap, stainless steel jacketed pipe sections, or stainless steel or aluminum flashings, and storm collars. We may also recommend that clients use commercially available combustion-enhancing, acid-neutralizing fuel additives to prevent damage caused to vents from sulfuric acid.

[Type B and Type L Vent Inspection, by N. Gromicko]